Acrylic signs are incredibly versatile because the creative options are limitless. Also known as plexiglass, acrylic comes in a variety of colors and opacities. Backlit signs, hi-end product displays, and environment and wayfinding signs only tell part of the story.

Acrylic Signs with Dimension

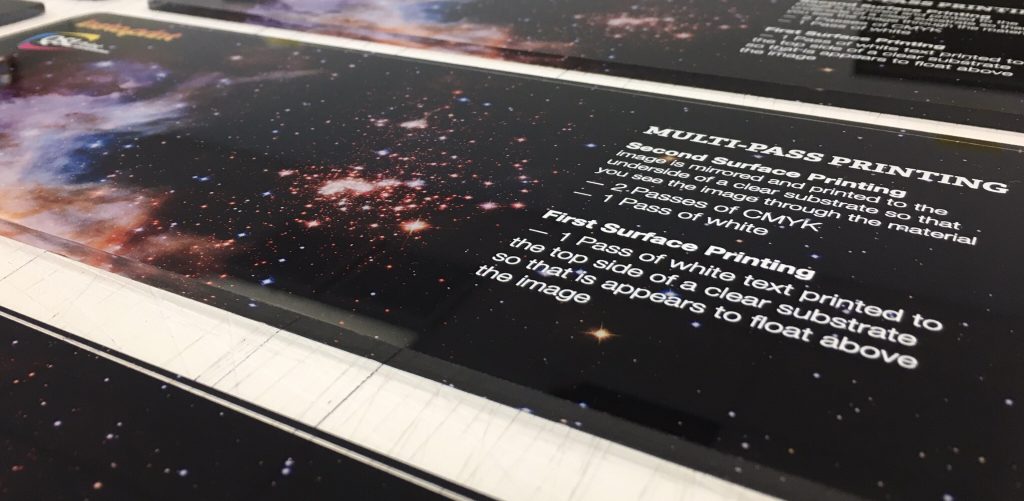

Make your text float, create real drop shadows, and make everything look cool. Double-sided printing creates dynamic, multi-dimensional art. Backgrounds shimmer through the glossy clear acrylic while text or logos hover above.

This article profiles the creation of our acrylic print samples. We designed these samples to showcase the creative possibilities when using multiple ink layers on a clear surface.

Direct-To-Substrate Printing

Combining imagery from two sides of a clear substrate requires a direct-to-substrate printer. First, we printed a mirror image of the Hubble photograph. This is called second-surface printing and it allows the image to be viewed through the substrate.

As soon as we took the piece of acrylic off of the printer, we knew we were going to need more opacity. One layer of ink let too much light through the print, making it look washed out. This would not do. We put the acrylic back on the printer and added a layer of white over the top of the first print. This may seem counter-intuitive but remember that the image is viewed through the substrate. The layer of white actually sits behind the image. The extra layer provided the opacity needed to make the print really pop.

Multi-pass Printing

The beauty of our direct-to-substrate printer is our total control of simultaneous ink layers. Once we determined that the Hubble image needed an extra layer, we were able to adjust the print settings to add the layer of white at the same time as the CMYK photo image, thus two passes of the printer became one.

We incorporated the same two-layer print method for the color logos on the primary print surface but with a twist. Instead of a flood white base, which would cover up the second-surface background, we needed the white to only print behind the logos. This is a process that gets set-up in the print file. We add a separate logo behind the visible layer, pull the lines in by a pixel or two, and then make the whole base logo a spot color that we can tell the printer to identify as white. The end result is what you see in the photo — white text and color logos that pop above the glossy background Hubble image. The best part is that all of these ink layers can be achieved with a single run of the printer for each side. Beauty and efficiency — this is creating printing!

See For Yourself

The true impact of this type of creative printing can only be experienced in person. Contact us to set up a tour. Maybe you’ll see something that inspires your next creative project.

* instaprint is a retail partner of QSL Print Communications *

| Privacy Policy | Home |